When it comes to large, open spaces, it can be a challenge to heating and cooling efficiently whilst saving costs. Some of these large spaces can include Warehousing, Retail Stores, Exhibition Halls and Manufacturing Workshops. At Reznor, we are experts when it comes to providing the best HVAC solutions for your desired space as we understand the pain points our customers experience. This is a necessary starting point to gain understanding of what requirements you need to fulfil, resulting in creating a better environment for your business. Let’s take a look at the top 2 pain points for heating and cooling Manufacturing Workshops and how Reznor can help combat them.

1. “Due to the size of the workshop, HVAC solutions are costly!”

This can be very true, as of course there is a larger expanse of area to look at bringing heating and cooling in, which may need multiple solutions. However, initially having an understanding of the importance of having effective heating and cooling shouldn’t be slept on. There are many reasons for it’s importance such as:

- Providing a comfortable and safe space for staff: this is vital to ensure a positive work environment that everybody wants to be in, which boosts morale and keeps everybody happy.

- Health & Safety regulations: some businesses need to follow certain legislations when it comes to ventilation and other air conditioning means, and this is a non-negotiable.

Saving costs is at the top of every business’ list due to inflation, that’s why at Reznor we create bespoke solutions suited to your workshop needs. Maybe you only require heating/cooling in certain areas of your space? We have you covered with our range of HVAC solutions, and it’s worth investing in efficient products that will save you energy and costs in the long run.

2. “Heating and cooling manufacturing workshops can be challenging to achieve efficiency…”

With many workshops having lots of empty space such as high ceilings and other areas of the building, heating and cooling can be tricky. Heat can rise to the unused space and be lost through frequent opening doors. We understand the needs of the manufacturing industry, as it is a constant cog turning therefore needing unique solutions for efficiency. Another pain point can be that employees only inhabit certain areas of the building, therefore heating can be wasted in the empty spaces. At Reznor, we have a few different options available to achieve better efficiency:

- Destratification fans can push rising heat back down to ground level, avoiding wasted warmth and reducing the amount of energy needed to heat the space.

- Air curtains create a barrier of air in doorways, which stops heat escaping and also prevents the ingress of insects and outdoor debris.

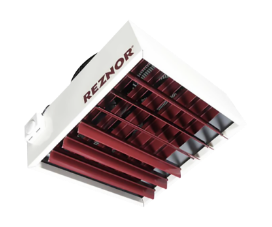

- Radiant heaters are usually suspended from the ceiling and provide heat only to specific areas, reducing costs by not wasting energy heating unnecessary areas.

Achieve effective air circulation and temperature regulation in your workshop

Another type of product to combat the above pain points are High Volume Low Speed (HVLS) fans, which are large diameter fans designed to circulate high volumes of air while operating at low speeds. They create more comfortable conditions for people through enhanced floor to ceiling air circulation and temperature regulation with lower energy utilisation.

This brings a sustainability factor, saving energy in the long run and working towards a better business environment. Raising the bar on high-tech fans, Powerfoil D is our premium direct-drive fan perfect for industrial and harsh environments. Its IP66 rating means it’s able to withstand harsh elements like dust and water.