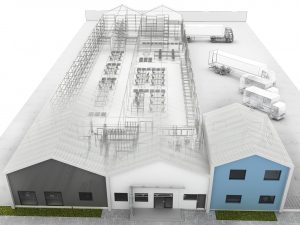

Business owners and facilities managers are always on the lookout to continuously improve their employee’s environment, whilst keeping a keen eye on running costs and contribution to our global carbon footprint. This is an ever-present factor when selecting HVAC equipment for their premises, particularly large production and warehouse spaces.

What are the five main challenges that you may have not considered?

1. Outside Air Infiltration

Minimizing or accounting for the frequent use of loading doors within the HVAC design process, and managing employee behavior. Try heating your bedroom with your window wide open!

2. Distribution of an even temperature

Large spaces usually have high ceilings, ensuring the right level of heat or cooling outputs for a space is only one part of the equation. Making sure that the temperature is consistent across the space or only allocated to specific zones is integral to a successful HVAC system.

3. Impact of process or other mechanical equipment on space temperature

Understanding what heat generating equipment is present within the space is imperative when sizing HVAC systems. Removal or the reuse of this energy can have a huge impact on the temperature within the space and your carbon footprint, utilizing waste heat to “free heat” other areas within a premises.

4. Adaptability for potential future changes to the use of the space

With the ever-changing business climate the use of a space can flex and change multiple times. This can be a challenge for many facility managers.

5. Running Cost control

Energy costs are always high on the agenda, therefore controllability and monitoring or energy use are vital to business profitability.